Brady Printers: i7500, i7100, i6100 – Why Choose Brady Over Zebra, Sato & Honeywell?

Posted by Midwest Barcoding Solutions on Oct 13th 2025

Why would you consider a Brady printer instead of the popular Zebra, Sato or Honeywell models?

Great question, and this article will seek to answer this.

While you are likely familiar with the industrial leaders of general-purpose barcode and logistics printing, a fundamental difference exists when the job demands more than just a paper shipping label. Brady's dominance is in providing specialized, unique, and niche identification and tagging solutions engineered for environments where standard labels fail. From electrical components exposed to extreme heat and chemicals, to manufacturing traceability on tiny circuit boards, to laboratory samples stored in cryogenic freezers, nobody has the complete, high-performance turn-key solutions—the integrated printer, material, and software system—like Brady. Hands down, they offer the best system for reliable, high-stakes identification.

The Brady Tabletop Portfolio: i7500, i7100, and i6100

In addition to a world-class labeling, identification, and tagging portfolio, Brady also has a lineup of tabletop (larger format) thermal printers to help deliver these solutions. This article focuses specifically on their industrial-grade workhorses: the BradyPrinter i7500, BradyPrinter i7100, and the BradyPrinter i6100. These models are built for high-volume environments that require precision and a unique ability to print on demanding materials.

The Flagship: BradyPrinter i7500

The BradyPrinter i7500 is the pinnacle of the portfolio, positioned as the Smart, High-Volume, Zero-Waste industrial printer. Its primary functionality revolves around dramatically improving operational efficiency. The defining feature is LabelSense™ Technology, a proprietary system that allows the printer and the specialized Brady supplies to communicate bi-directionally.

This smart technology eliminates the tedious and wasteful tasks common with traditional printers. There is no need for manual calibration, heat adjustments, speed settings, or sensor positioning; the i7500 handles it all automatically. This auto-setup capability allows operators to change materials in as little as 40 seconds with zero wasted labels, printing accurately on the very first part. Designed to handle print volumes up to 7,000 labels a day, the i7500 is the ideal choice for high-mix production lines where minimizing operator error and maximizing material efficiency is a top priority.

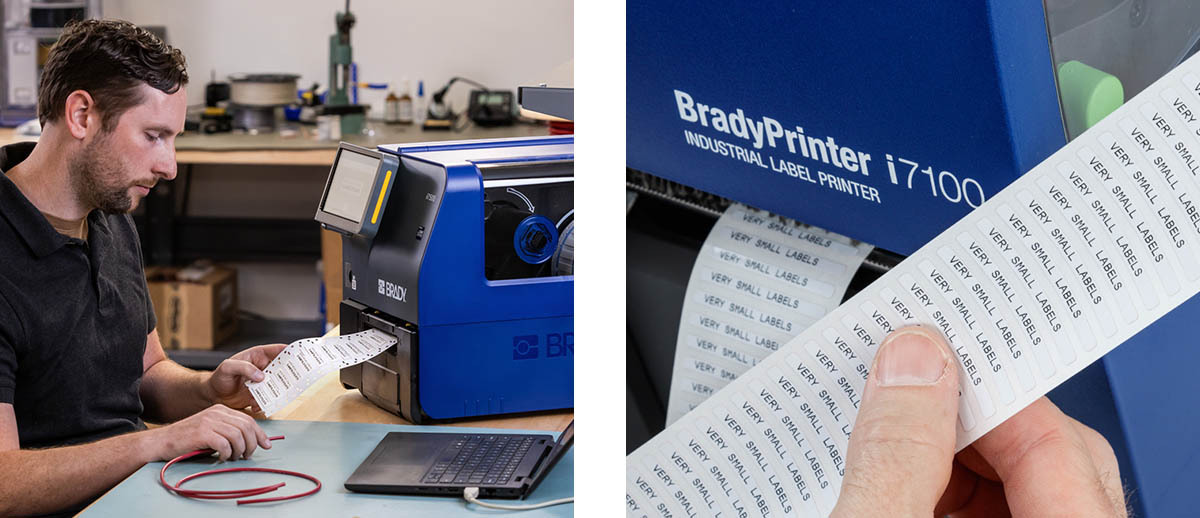

The Precision Workhorse: BradyPrinter i7100

The BradyPrinter i7100 is the portfolio’s Extreme Versatility and High-Resolution Precision champion. It is specifically engineered to handle the widest range of high-performance and difficult-to-print Brady materials, including thick heat-shrink sleeves, continuous cable tags, and rugged industrial polyester.

What sets the i7100 apart is its ability to be configured with a 600 dpi printhead option. This ultra-high resolution is essential for applications requiring tiny text, micro-sized barcodes, or complex serial data on small components (down to 0.125 inches). Like the i7500, it is built for print volumes up to 7,000 labels per day, but it is the go-to printer when the most challenging materials and the highest print clarity are non-negotiable requirements.

The Industrial Foundation: BradyPrinter i6100

The BradyPrinter i6100 is the Durable, Entry-Level Industrial Workhorse. It offers Brady's renowned rugged reliability and strong material compatibility at a more accessible entry point. Featuring a sturdy aluminum frame and a robust construction, the i6100 is engineered to withstand demanding industrial environments.

With high-speed printing capabilities that support up to 4,000 labels a day, the i6100 is ideal for businesses needing dependable, high-volume day-to-day industrial labeling without the most advanced automation features of the i7500 or the extreme precision of the 600 dpi i7100. It provides the essential blend of speed, durability, and access to a wide range of Brady's core materials.

Deciding Which Printer is Best Suited

A company determines the best fit by prioritizing their needs:

- Choose the i7500 if you have high material turnover, high operator turnover, and need to minimize consumable waste and setup time through smart automation.

- Choose the i7100 if you require 600 dpi precision for tiny component marking, or if you print on the most specialized and challenging materials like thick cable sleeves.

- Choose the i6100 if you need a durable, high-volume industrial printer that consistantly prints compliant labels and is focused on foundational reliability.

Common Use Cases and Problems Solves

Brady solutions are deployed when the cost of identification failure is high. These printers and their materials solve specific challenges across industries:

- Electronics Manufacturing & Traceability: They print tiny polyimide labels that survive the extreme heat and chemical exposure of wave soldering on Printed Circuit Boards (PCBs), solving the problem of traceability loss during manufacturing.

- Aerospace & Defense: They create wire and component markers that meet strict military (MIL-STD) or industry (NAS) compliance standards, ensuring asset integrity under conditions of abrasion, fuel, and extreme temperature fluctuations.

- Life Sciences & Laboratory: They enable printing on cryogenic labels that must remain adhered and legible in liquid nitrogen storage (−196∘C), preventing critical sample loss and data corruption.

- Industrial & Electrical: They produce self-laminating wire wraps and cable tags that resist dirt, oil, and solvents, solving the problem of electrical downtime caused by illegible or missing identification.

Pricing and Total Cost of Ownership (TCO)

Brady printers occupy the premium industrial printer segment. While the initial investment for the i7500 and i7100 is often higher than many base models from Zebra, Sato, or Honeywell, the focus shifts to a favorable Total Cost of Ownership (TCO).

The TCO advantage for a Brady Printer is found not in the hardware price, but in the long-term operational savings and system reliability. Because Brady engineers the printer, the software, and the material to work together, their system minimizes wear and tear. Features like the i7500's zero-waste setup and optimized ribbon feeding directly reduce wasted specialized material—which is typically the highest operating expense. This engineered harmony also results in extended printhead life and reduced maintenance needs, directly cutting down on parts replacement and system downtime compared to open-architecture systems that often struggle to print difficult media reliably. The result is a lower cost per compliant label, which is the true metric for success in specialized identification.

Why Choose a Brady Printer Over a Competitive Model?

The answer is the absolute guarantee of performance offered by the closed, integrated Brady System.

The most critical competitive advantage is that many of Brady’s high-performance label materials are exclusive and specifically engineered to communicate with and be printed by their machines. A standard industrial printer may claim to print on vinyl or polyimide, but it cannot guarantee that label will survive ten years in a manufacturing environment or maintain legibility in −196∘C storage.

The i7500's LabelSense™ Technology is a powerful function that competitive models lack, removing the guesswork and expertise required for printing high-mix, demanding labels. The system essentially self-calibrates. While competitors focus on providing a versatile "box" compatible with generic consumables, Brady focuses on providing the definitive "solution" where the material, the printer, and the software (Brady Workstation) are factory-optimized to deliver maximum durability and compliance, print after print.

5 Crucial Questions for Business Consideration

When evaluating a Brady Printer over industry leaders such as Zebra, Sato or Honeywell, a business must answer the following crucial questions:

- What is the Quantifiable Cost of Label Failure in Our Operation? (

If a failed label—due to fading, falling off, or illegibility—leads to regulatory non-compliance, production shutdown, or critical sample loss, the precision and reliability of the Brady system is warranted.) - Are We Frequently Wasting Specialized Label Materials Due to Setup and Calibration Errors?

(A "yes" indicates an immediate, measurable ROI for the Brady i7500 and its LabelSense™ zero-waste technology.) - Do Our Labels Require Ultra-High Resolution (600 dpi) or the Ability to Print on Difficult Materials Like Heat-Shrink Sleeves?

(This technical requirement points directly to the versatility and precision of the Brady i7100.) - How Much Downtime and Maintenance Expense Are Currently Attributed to Printhead Issues or Media Misfeeds on Specialized Materials?

(Brady's integrated system reduces the stress on printheads and minimizes media errors, driving down long-term maintenance costs.) - What is Our True Cost Per Compliant, Finished Label?

(By shifting the focus from the initial hardware price to the lifetime cost of wasted consumables and minimized labor/downtime, the total value proposition of the Brady system becomes clear.)

Talk to an Expert