Cheap Barcode Labels: 9 Hidden Risks That Cost You More

Posted by Midwest Barcoding Solutions on Dec 7th 2025

In warehouses, retail stores, hospitals, and manufacturing plants around the world, barcode labels are the unsung heroes of efficiency. They track inventory, ensure patient safety, guide assembly lines, and prevent costly shipping errors. When everything works, nobody notices the label. When something goes wrong, the label is often the first thing blamed—and for good reason.

Most organizations know the big-name label manufacturers: Zebra, Brady, TSC, and Printronix. These companies have a reputation for premium pricing, and yes, their labels usually cost 20–60% more than the flood of generic, off-brand, or “compatible” alternatives now available on Amazon, Alibaba, and dozens of online resellers.

For simple direct-thermal or thermal-transfer paper labels (the white or lightly colored stickers used for shipping labels, basic inventory tags, or short-shelf-life applications), many buyers reason that the savings outweigh the risks. After all, if a cheap barcode label fails, you can just slap on another one, right? But as someone who's seen the fallout from skimping on quality, I can tell you that's a shortsighted view. Those low-price barcode labels might seem like a bargain upfront, but the hidden costs—from printer damage to operational nightmares—can quickly erase any savings and then some.

Let's dive into the real risks of opting for generic barcode labels over trusted name-brand suppliers. We'll cover everything from material inconsistencies to compliance headaches, drawing from industry insights and real-world examples. If you're considering knock-off barcode labels or cheap thermal labels from lesser-known converters like Buckeye labels, Kroy labels, or Smith Corona labels, read on. You might just decide that sticking with proven players like Zebra or Brady is worth the extra bucks.

1. Inconsistency in Thermal Label Materials

One of the biggest pitfalls with third-party barcode label manufacturers is the inconsistency of their thermal label materials. To keep prices rock-bottom, these converters often switch suppliers frequently, chasing the cheapest raw materials available. What you get today might be worlds apart from what you ordered six months ago—even if it's from the same vendor.

This variability can wreak havoc on your operations. For instance, differences in paper thickness, coating quality, or chemical composition might not be obvious at first glance, but they show up in subtle ways: uneven print quality where barcodes appear fuzzy or faded, reduced durability leading to premature wear, inconsistent appearance that makes your branding look sloppy, or adhesives that don't bond as reliably to surfaces.

Imagine a warehouse where labels from one batch stick perfectly to cardboard boxes, but the next batch peels off during transit due to a cheaper adhesive formula. That's not just annoying—it's a recipe for lost inventory and frustrated customers. Name-brand manufacturers like TSC or Printronix maintain strict quality controls, sourcing consistent materials that perform predictably every time. With generics, you're essentially gambling on each roll.

2. Constant Vendor Switching: A Lack of Predictability for End-Users

Building on that, the relentless pursuit of low costs forces third-party manufacturers to hop between vendors constantly. It's like shopping at a discount store where the stock changes weekly—you never know what you're getting. This leads to a profound lack of predictability, making it hard for businesses to standardize their processes.

For end-users, this means recalibrating printers more often, dealing with unexpected failures, or even retraining staff on handling "quirky" labels. In high-volume environments, like e-commerce fulfillment centers, this inconsistency can snowball into downtime and inefficiencies. Trusted brands like Zebra invest in long-term supplier relationships to ensure every batch meets the same high standards, giving you peace of mind and operational stability.

3. Shortened Printhead Life: The Expensive Wear and Tear

There's no sugarcoating it: cheap barcode labels accelerate wear on your printer's printhead. Generic materials are often rougher and more abrasive, grinding away at the delicate components inside thermal printers. Over time, this buildup of residue and friction can shorten printhead life by 20-50%, depending on usage.

Replacing a printhead isn't cheap—costs can range from $200 to over $1,000 per unit, plus labor and downtime. If your operation runs through dozens of printheads a year, those "savings" from low-price barcode labels evaporate fast. Studies and industry reports show that subpar labels cause excessive buildup, requiring more frequent cleaning and servicing. Brands like Brady and Zebra design their labels to minimize abrasion, often including protective coatings that extend hardware life. Zebra even offers a 100% printhead protection plan when you use their genuine supplies, covering replacements for normal wear—something generics can't match.

4. Missing CSA/UL Certifications: Skimping on Safety and Standards

Certifications like CSA (Canadian Standards Association) and UL (Underwriters Laboratories) aren't just badges—they're assurances of performance, durability, and safety. Most third-party manufacturers skip these because the testing and compliance processes eat into their slim margins.

Without these certifications, your cheap thermal labels might not hold up in regulated environments, like food processing or electrical applications, where labels need to withstand heat, chemicals, or moisture without failing. This oversight can lead to safety hazards, such as labels detaching from equipment and causing misidentification. Name-brand suppliers like Printronix prioritize these standards, ensuring their products meet or exceed industry requirements and protecting your business from liability.

5. Overall Low Quality: From Adhesives to Scannability

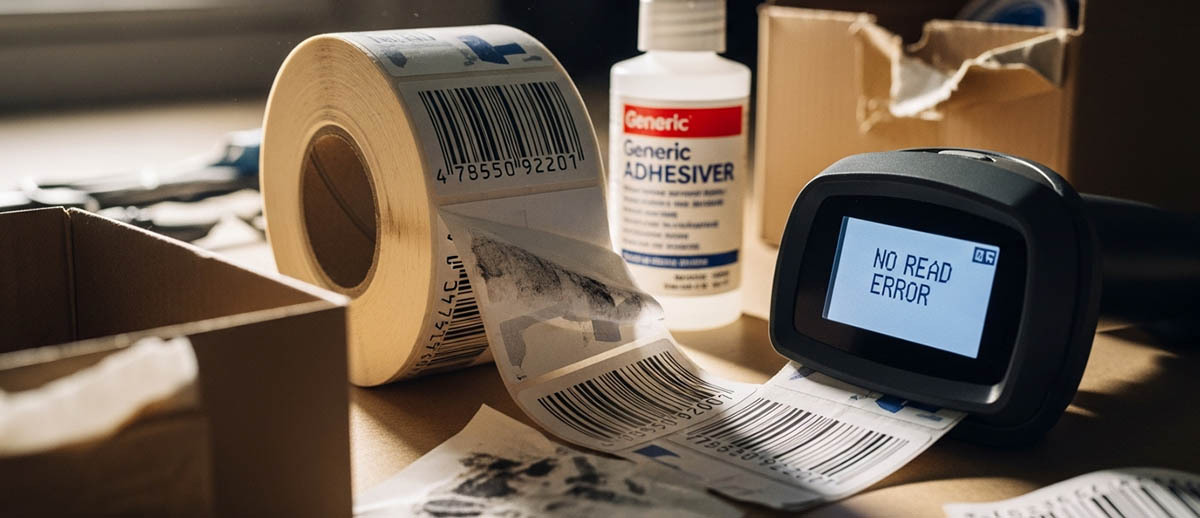

Cheaply sourced materials spell trouble across the board. Adhesives that don't stick properly can cause labels to peel off mid-shipment, leading to unscannable barcodes and delivery errors. Faded or light print from inferior inks makes barcodes unreadable under scanners, forcing manual interventions that slow everything down.

Worse still, low-quality labels often shed particulate matter—tiny flakes of paper or coating that clog printer sensors, dirty the platen roller, and further damage the printhead. In manufacturing, this can halt production lines, costing thousands in lost productivity. Knock-off barcode labels from brands like Buckeye or Kroy might look similar, but they lack the refined engineering of Zebra or Brady products, resulting in messy, unreliable performance.

6. Questionable Trust and Integrity: Prioritizing Profits Over Performance

At the end of the day, any supplier that chases the lowest price at the expense of quality is signaling their priorities loud and clear. Businesses built on trust, like TSC or Printronix, stand behind their products with warranties, support, and consistent innovation. Generic manufacturers? Not so much. They're often fly-by-night operations focused on volume over value, leaving you high and dry when issues arise.

Choosing a partner with integrity means investing in long-term success, not short-term savings that bite back.

7. Compatibility and Application Mismatches: Not One-Size-Fits-All

Another risk often overlooked is compatibility. Generic labels aren't always optimized for specific printers or applications. For example, they might lack the right topcoat for high-speed printing or the adhesive needed for curved surfaces, extreme temperatures (-65°F to 200°F+), or exposure to water, chemicals, or abrasion.

This mismatch can cause labels to smudge, fade, or fall off in harsh environments, like outdoor storage or chemical plants. In contrast, Zebra offers over 1,000 label-ribbon combinations, pre-tested for their printers, ensuring seamless integration and durability. Using off-brand thermal transfer labels could void your printer's warranty, adding another layer of risk.

8. Operational Inefficiencies and Supply Chain Disruptions

Poor-quality labels don't just fail—they cascade into bigger problems. Unreadable barcodes lead to inventory errors, lost shipments, and manual tracking, which ramps up labor costs and error rates. In manufacturing, this disrupts picking, packing, and sorting, potentially delaying entire supply chains.

For retailers, unscannable labels can mean misplaced stock or customer complaints. One report highlights how incompatible labels cause downtime and wasted resources on reprints and adjustments. High-quality options from Brady minimize these issues, keeping operations smooth and efficient.

9. Regulatory Compliance Risks and Potential Fines

In regulated industries, the stakes are even higher. Generic labels might not comply with retailer standards, like Walmart's UCC-128 requirements, leading to chargebacks—penalties per shipment for unscannable or non-compliant labels. Fines can add up quickly, especially for high-volume shippers.

Non-adherence to industry specs for label design, placement, or durability can result in compliance violations, escalating costs and damaging reputations. Trusted manufacturers like Zebra ensure their products meet these standards, helping you avoid costly penalties.

The True Cost of Going Cheap

Sure, cheap barcode labels tempt with their low upfront price, but as we've seen, the risks—inconsistency, printer damage, quality failures, and beyond—can turn that "bargain" into a budget-buster. From shortened printhead life to supply chain snafus and regulatory headaches, generics like those from Smith Corona or other third-party sources often deliver more headaches than value.

Investing in name-brand barcode labels from Zebra, Brady, TSC, or Printronix isn't about splurging—it's about smart business. Their unrivaled quality, consistency, and support translate to fewer failures, lower long-term costs, and peace of mind. Next time price drives your decision, ask yourself: Is "just replace it if it fails" really a strategy, or a shortcut to bigger problems?

If you're shopping for reliable barcode labels, start with the pros. Your operations (and your wallet) will thank you.

Talk to an Expert